Logs & kindling can be easily dried for use and sale with our hot air heater

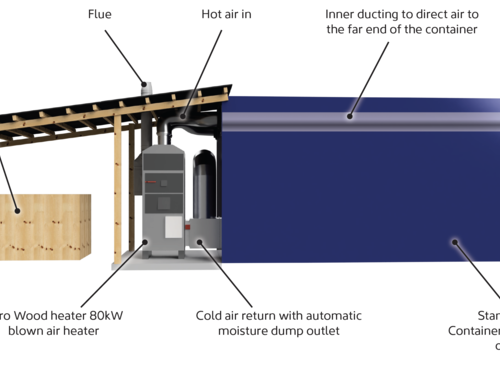

Zero Ridge range of purpose-built hot air drying equipment.

Hot air heaters for your own drying rooms/buildings.

Our range of heaters can be easily adapted to suit your applications. From the smallest drying room to largest bulk drying buildings.

Dry almost anything...

| Logs | Wood Planking |

| Hemp | Grass |

| Straw | Foodstuffs |

| Flowers | Miscanthus |

| Grain | Wood Chips |

| Hops | Herbs |

| Seaweed | Salt |

| Evaporation |

Purpose-made drying chambers, rooms and cabins.

Zeroridge can supply purpose made drying systems ready for you to operate.

-

Small single box drying stores fitted with F28 or F55 hot air heaters.

-

Medium multi-box drying stores for 2-3 stillages fitted with F55 or F85 hot air heaters.

-

Large multi stillage dries for 4-8 stillages fitted with F85-F120 hot air heaters.

-

Conveyor driers for continuous stillage processing. Fitted with F120-F240 hot air heaters.

Why use our Hot Air Heater to Dry wood.

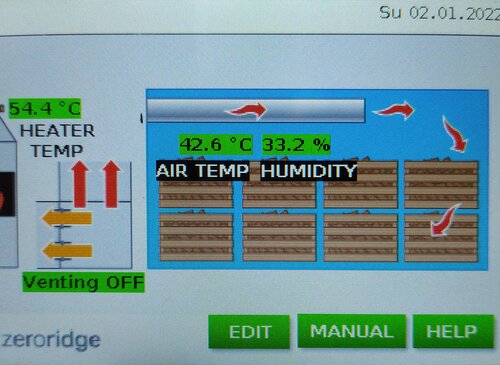

Our hot air heaters are robust and simple to use. They can burn wood logs, pallet wood and offcuts to produce high-temperature hot air to dry whatever you wish.

Our range sizes can suit all possible requirements from a small home drier to large commercial applications.

Why use our Hot Air Heater to Dry wood.

Our hot air heaters are robust and simple to use. They can burn wood logs, pallet wood and offcuts to produce high-temperature hot air to dry wood.

Our range sizes can suit all possible requirements from a small home drier to large commercial applications.

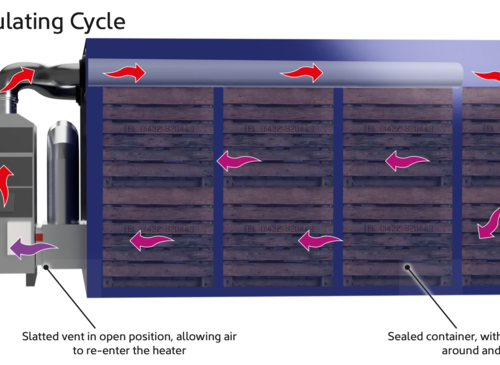

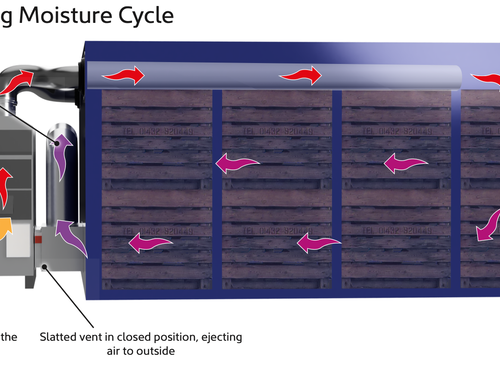

Wood Drying Basics

The water inside wood moves from a higher to a lower zone of moisture content.

In other words, “wood dries from the outside in.” This means that the surface of the wood must be drier than the interior if moisture is to be removed.

The drying process can be broken down into two phases:

1. The movement of water from the interior towards the surface of the wood.

2. The removal of water from the surface.

The water inside wood is held as free water and bound water. Free water is contained inside the cell cavities, and bound water is held within the cell walls. Free water within the cell cavities is held less tightly than bound water within the cell walls. Consequently, slightly more energy is required to remove bound water than free water. Free water does not affect as many wood properties as bound water. The removal of bound water affects many physical and mechanical properties and therefore affects the quality and use of the wood.

The fibre saturation point (FSP) is defined as the moisture content at which “free water is completely gone, while the cell walls are saturated with bound water”. In most types of woods, the fibre saturation point is roughly at 25 to 30% of moisture content.

- Low priced hot air heating.

- Dry all sorts of products.

- Build your own drying systems.

- Let us build one for you.

- Simple to use.

- Simple to install.

- Quick warm up.